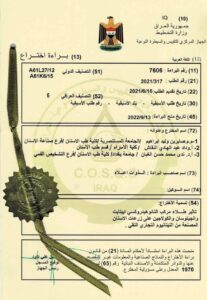

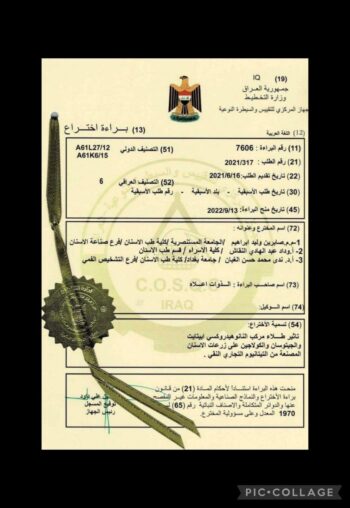

The researcher Dr. Nada Muhammad Hassan Al-Ghabban, at the College of Dentistry – University of Baghdad, has granted a patent for her ability to manufacture pure commercial titanium implants coated with nanohydroxyapatite, chitosan and collagen. A commercially pure titanium rod was machined into 54screws shaped implants. Implants were divided into 3 groups according to the types of coating used: 1st group (18 implants) coated by dip coating with nano hydroxyapatite (control), 2nd group include (18 implants) coated by dip coating with nano hydroxyapatite and chitosan composite, and 3rd group include (18 implants) were coated by dip coating with nano hydroxyapatite, chitosan and collagen composite.

Evaluation of surface chemical characteristics after coating (in vitro study) was done by Fourier transfer infrared (FTIR) analysis and for evaluation of surface topography by scanning electron microscope (SEM) analysis and microscopical examination. The tibiae of 18 white New Zealand rabbits were chosen as implantation sites. Six implants for each type of coating were tested for torque removal test to measure bond strength between implant and bone for each period of healing, three screws for each type of coating were used for histological analysis after each healing period (2,6 weeks).

The patent aimed to enhance bone healing process around dental implants.

This patent can help to manufacture implants for missing teeth in dental implant centers at the Ministry of Health